Services

PET Preform Manufacturing

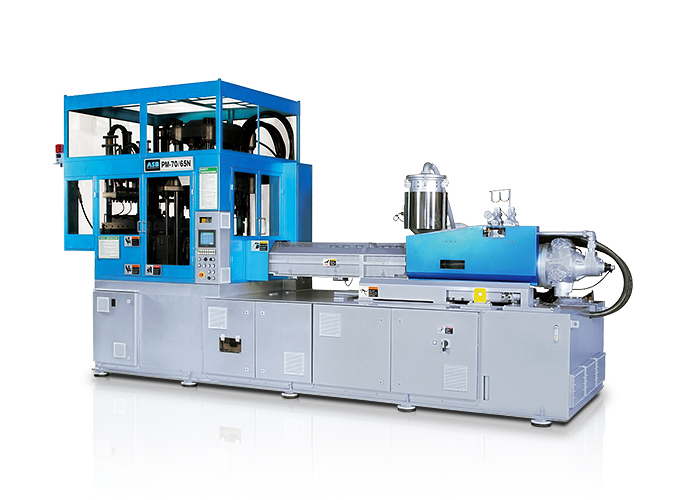

Our PM-70/65N II preform molding machines utilizing ASB’s well proven vertical clamping system. Compact and strong, it provides accurate and stable molding while maintaining fast cycling. Excellent cost performance is achieved through low energy consumption (about 40% less power consumption) by the use of twin variable displacement hydraulic pumps.

Preforms for various type of bottles such as water, CSD, heat-resistant bottles and up to 5L bottleshaving 28 to 48mm neck diameter can be molded with 8 to 24 cavities.

-

1 Newly designed

injection unitNewly designed injection unit with simplified hydraulic circuit offering consistent operation and outstanding reliability.

-

2 Injection holding

pressure cylinderThis feature allows screw charging to start during holding pressure time enabling high shot weight with minimun cycle time. It contributes to AA reduction as well.

-

3 High-speed

preform moldingMaximum 24 cavities (3 rows) *1 are available in small space.

Gateless hot runner system avoids need of gate-cutting system.

Lip cavity is directly cooled by chilling water to reduce the separating time from the mold.

Light weight design of movable part enable the faster mold movement.

-

4 Increased

cooling efficiencyMolden preforms are directly transferred to the cooling block without any interim transfer, allowing post-molding cooling to start immediately.

Using vacuum, preforms are forced to touch the inside of the cooling block, so they are cooled efficiently.

Linear movement of preform rows is controlled by servo-motors, achieving fast, accurate positioning and energy saving.

Preforms are cooled evenly during 4 injection cycles.

PM-70/65NII Preform Molding Machine

- Materials

- PET, PP

- Shapes

- Preform